Butterfly valves are incredibly popular in the industrial sector due to their ability to regulate flow and pressure in pipelines. Among the various types of butterfly valves is the cast iron butterfly valve, which has been the go-to choice for many oil and gas, chemical, and water treatment facilities. This valve is designed to handle a wide range of applications that demand durability, corrosion resistance, and high flow rates.

In this blog post, we’ll cover everything you need to know about cast iron butterfly valves, including their working principle, advantages, applications, and how to select the right valve for your project. We’ll also discuss the differences between cast iron butterfly valves and cast iron ball valves, two types of valves that are often compared.

Working Principle of Cast Iron Butterfly Valves

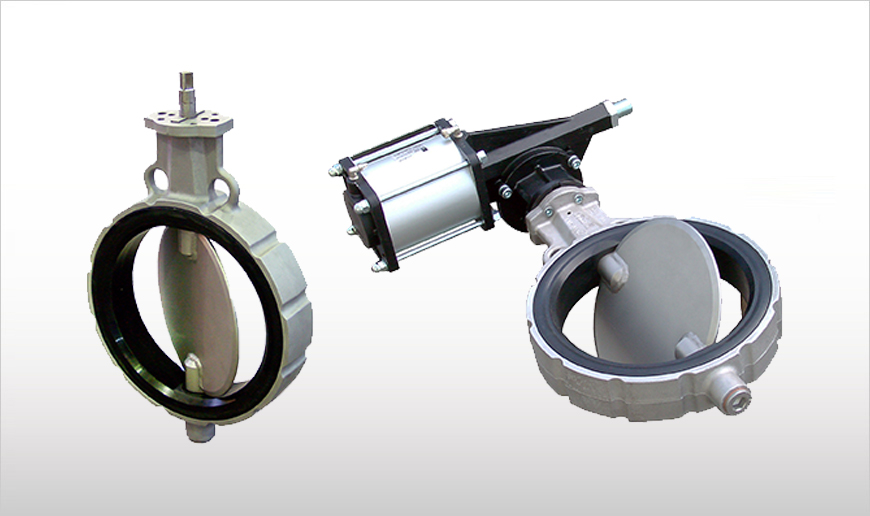

A cast iron butterfly valve comprises a disc, a stem, a body, and a seal ring. The disc is a circular plate that rotates around an axis to control the flow of fluid in the pipeline. When the valve is fully open, the disc is parallel to the flow direction, allowing maximum flow rates. When the valve is partially or fully closed, the disc is perpendicular to the flow direction, blocking the flow.

The stem connects the disc to the actuator, which is the device that controls the valve's movement. The actuator can be manual or automatic, depending on the application requirements. The body is the main part of the valve that houses the disc and the stem. Finally, the seal ring is the component that forms a tight seal between the valve body and the disc, preventing leakage.

Advantages of Cast Iron Butterfly Valves

Cast iron butterfly valves offer several advantages over other types of valves, including:

- High flow capacity: The disc design of the valve allows for high flow rates, making it ideal for applications that require large volumes of fluid to be transported.

- Easy installation and maintenance: Butterfly valves have a simple design, making them easy to install and maintain. They also require less space than other types of valves, making them ideal for tight spaces.

- Durability: Cast iron butterfly valves are highly durable and resistant to wear and tear, making them suitable for harsh environments.

- Corrosion resistance: Cast iron butterfly valves are resistant to corrosion and can withstand harsh chemicals.

Applications of Cast Iron Butterfly Valves

Cast iron butterfly valves are used in various industries that require flow control and pressure regulation, such as:

- Oil and gas: Butterfly valves are commonly used in oil and gas pipelines to control the flow of gas and oil. They are also used in refineries and petrochemical plants.

- Chemicals: Butterfly valves are used in chemical processing plants to regulate the flow of various chemicals, including acids and alkalis.

- Water treatment: Butterfly valves are used in water treatment facilities to regulate the flow of water, including waste water treatment plants and municipal water supply facilities.

- HVAC systems: Butterfly valves are used in heating, ventilation, and air conditioning systems to regulate the flow of air and water.

Cast Iron Butterfly Valves Vs Cast Iron Ball Valves

Cast iron ball valves are another popular type of valve used in industrial applications. These valves have a spherical ball with a bore that allows fluid to pass through when aligned with the pipeline. When the valve is closed, the ball rotates 90 degrees, blocking the flow.

While both cast iron butterfly valves and cast iron ball valves have similar functions, there are some key differences between the two. Cast iron butterfly valves offer higher flow rates and are better suited for larger pipes. They also require less space and are easier to install and maintain.

On the other hand, cast iron ball valves are better suited for low flow and high-pressure applications. They are also more reliable in harsh environments, making them ideal for oil and gas pipelines that transport corrosive fluids.

Choosing the Right Cast Iron Butterfly Valve

When selecting a cast iron butterfly valve, there are several factors to consider, such as:

- Operating conditions: Consider the temperature, pressure, and nature of the fluid being transported.

- Valve size and connection type: Be sure to choose a valve that fits your pipeline size and connection type.

- Type of actuator: Choose an actuator that meets your application requirements, whether it's manual, pneumatic, or electric.

- Material: Cast iron butterfly valves are available in different materials, including cast iron, stainless steel, and PVC. Choose a material that is suitable for your application.

Conclusion

Cast iron butterfly valves are a vital component in many industries that require flow control and pressure regulation. They offer several advantages over other types of valves, including high flow capacity, easy installation and maintenance, durability, and corrosion resistance. When selecting a cast iron butterfly valve, it's essential to consider the operating conditions, valve size and connection type, type of actuator, and material. By choosing the right valve for your application, you can ensure optimal performance and maximum efficiency.

Keywords: Cast Iron Butterfly Valves, Cast Iron Ball Valve, Flow Control, Pressure Regulation, Industrial Applications.